Quality Control

Quality process is the most important area of what we do at Morris Engineering. This process ensures that our clients can rely on their machined components being exactly correct to the design specification. From the moment something is checked out of our bonded materials store it is accounted for through each stage of machining and finishing right through to dispatch.

Morris Engineering invest heavily in this process as it is the spine of our operation. Quality starts when a job card is issued, with a quality check within stores for the materials, then via the production engineer for program, tooling and fixtures. Quality check is carried out regularly during production with an inspection for 1st off. Final inspection is carried out on the order before shipment is made to our client. Our quality control systems continue through to receipt by the customer and detailed job records ensure subsequent orders precisely match the original specifications.

We have a specialist in house Quality Clinic which investigates any problems with quality so that they are eradicated within manufacture, allowing short delays to be quickly overcome so that production can quickly continue and clients delivery deadlines met.

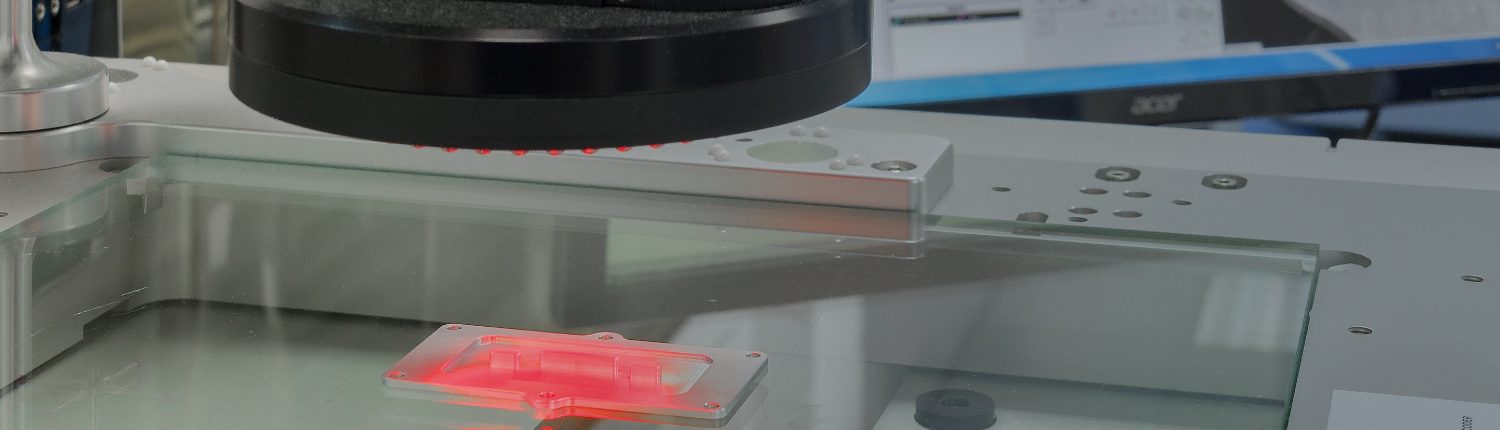

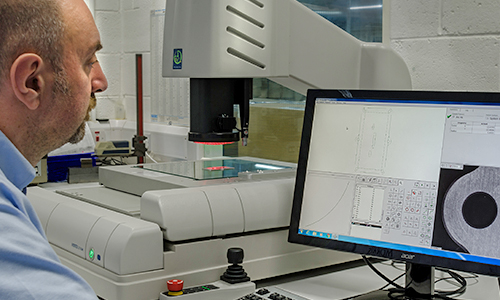

Continued investment in the latest software and technology to measure components has propelled Morris Engineering to the fore-front of delivering to specification and continues to facilitate our growth via client satisfaction and return.